Summary comments presented at Kaivalam Craft Summit, World Crafts Council General Assembly, Chennai 7-10 October 2012

Mrs Usha Krishna opening Kaivalam

We’ve just shared three days of talks from extraordinary people from all corners of the world about the state of craft today. What have we learned?

There have been some important proposals for us to consider. The most salient of these has been the development of an Academy of Craft & Design, presented by the Indian Minister of Handicrafts, Anand Sharma. That I could read about this in the Times of India yesterday is testament to the usefulness of the World Crafts Council presidency to the host nation. It is a great credit to the influence of Mrs Usha Krishna that she has been able to leverage the occasion for strategic political announcements of benefit to the craft sector. We hope the academy, when finally built, will prominently feature her portrait in recognition of her resounding contribution to craft.

Looking more behind the scenes, we had advice about the need to know ourselves better, in particular to collect data that could translate our blind passion for craft into cold hard statistics. Ashoke Chatterjee spoke about this in the Indian context, contrasting the excellent business case of the craft export centre against the largely opaque local sector. Simon Ellis offered us some recent models for quantifying craft used by organisations like UNESCO.

Proposals like these will depend partly on factors beyond our control, particularly government budgets. While we need to follow up on these beyond Kaivalam, it is important that we find ways of continuing the conversation started here.

The Sari Production by Daksha Sheth, telling the story of weaving a sari from beginning to end in vigorous dance and music.

As I attempted to distil the learning of Kaivalam last night, I was inspired by the wonderful Sari Production that we witnessed, where dancers performed the marvellous process of sari weaving and wearing. They beautifully conveyed the back and forward of the shuttle that is intrinsic to weaving. And so, thinking about our discussions, rather than define our agreements, it seemed more appropriate to identify the dualities that energised our discussions. While here in India, it seems important to take one of its principle learnings, Dharma, as a framework for thinking about the dualities that have been revealed in world craft over the past three days.

While one side tended to dominate in Kaivalam, the other was evoked. Our ongoing discussion aims to weave a dense fabric of understanding moving between the two alternatives.

What is the best market for craft?

On the second day, we heard some very impressive case studies for the support of traditional craft through the luxury market. These included opportunities discussed by Marcella Echavarria for appealing to consumers in New York through clever branding, Umang Hutheesing’s continuing revival of the courtly traditions that thrived under the Maharajas, Rolf von Buerren’s tribue to the vision of the Queen of Thailand in sponsoring her country’s craft, and the marvellous tale of Jean François Lesage’s work in servicing the restoration of European aristocratic treasures through Chennai craftsmanship

There is no doubt that royalty has played a positive role in the development of craft excellence and exquisite technical skill. As craft becomes increasingly rare, it also gains in exclusive value. And if we argue that wages for artisans need to increase, we should look to the wealthy who are the ones that can afford to pay the higher prices. It seems a good bet.

But then on the other hand, as Ms Souad Amin from Lebanon asked, is craft just for the elite? Actually, the dominant story of craft invoked on the first day was that of Gandhi, who saw spinning as a spiritual exercise for the strengthening of the Indian nation after British rule. So where was the spirit of the hand-spun khadi cloth today—craft for every person and every day? In Kaivalam, this found its expression largely in the corporate sector. We heard from Janet Nkubana about how she has been able to create a craft industry for her fellow Rwandan women supplying the Wal-Mart chain in the United States. We had Ratna Krishnakumar’s beautiful presentation of saris made by the Pochampalli weavers, now providing uniforms for the Taj Hotels. For those who are able and interested to make a regular supply of craft products, there are many new opportunities to connect with corporate outlets.

On the one hand, luxury boutiques. And on the other hand, supermarkets. Both alternatives exist very much within the existing market system. Maybe there’s also a space for craft that connects people more directly than through the market. We need to think more about the egalitarian role of craft, in particular how to reconcile the DIY movement with world craft.

How can countries partner together?

As has been evident thus far, the World Crafts Council is a multifaceted forum for bringing together many different cultures of the world.

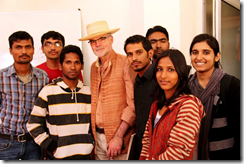

Apart from sharing a solidarity through our own individual craft traditions, the question was raised of how we can collaborate together as partners. This is particularly evident in the paper about India-Africa partnerships at NID given by Frances Potter and Shimul Vyas. As Frances said, she had presumed that all possibilities came from the north, but she just woke up one morning and thought of India. I wonder what she dreamt of during the night.

The Zimbabwe-India partnership is a perfect example of the kind of south-south cooperation that is growing so strongly now, most evident in the rise of the BRICS trading block. Of course, it is particularly strong right here in the audience of the General Assembly, where we see a growing proportion of countries from the global South. We are at the crest of the tide of history, particularly the Asian Century.

But we should never forget the North. As Adelia Borges reminded us, north-south relations can sometimes be a monologue. Northern designers can often commission craftspersons with little dialogue over the final product. But dialogue goes both ways, and we should also consider the North as an essential part of the World Crafts Council conversation. After all, it’s where the modern craft story began, with the Arts & Crafts Movement whose ideas expressed by William Morris and John Ruskin helped inspire the craft revivals in India, Japan and beyond. Today we see such innovative design emerging from countries like the Netherlands, Norway and the UK. We certainly witnessed this in Christa Meindersma’s presentation of works supported by the Prince Claus fund in the Netherlands.

On the one hand we have the South with its energy and vibrant traditions, and on the other we have the North with its modernist professionalism and institutions. Getting our two worlds to talk to each other with equal respect is a major challenge for world craft.

Kenya Hara answering the question about the space for craft

What is the space of craft?

One of the very surprising and thrilling discussions followed the talk by the Mooji designer, Kenya Hara. You’ll recall, he spoke about the aesthetic of emptiness and its role in design. Hara framed the place of emptiness in Japanese culture as an invitation to the gods. He contrasted this to way decoration on objects operates as an expression of power.

But then the Kuwaiti scholar Dr Ghada pointed out that in the Islamic tradition the purpose of decoration is to keep the devil out. From one end of Asia to the other we witnessed a clash of opposites—gods and devils, emptiness and fullness. Where might they meet?

When pressed on this matter, Hara observed that the very plainness of Mooji design offers a place for the crafted object to be more clearly apprehended. A simple table provides the perfect stage for a finely worked piece of craft.

This was an intriguing model for the role of design in craft: design makes a space for craft to express itself. Given the business and noise of contemporary life, making this space, what Heidegger calls the ‘clearing’, is particularly important.

On the one hand the emptiness of design, but on the other hand, the fullness of craft. As a curator, I find this duality particularly important.

How do we protect craft?

Then yesterday, we had an especially intense series of papers about Geographical Indicators. Here we learnt about the role of the law in protecting our craft knowledge. Geographic Indicators ensure that a community which has been the custodian of a particular craft tradition will be the exclusive owners of that intellectual property. These Geographical Indicators are an important addition to the legal arsenal alongside copyright, patents and traditional knowledge.

But there is also the parallel effort to protect craft from imitation and knock offs, which doesn’t rely on lawyers or courts—marketing. Today craft organisations organisations can develop websites that include images of their artisans, perhaps even videos, so the ethical consumer can feel more confident about their authenticity. More practically, this information offers a story that they can then use when sharing their purchase with others or directly when presenting it as a gift.

So we have two quite different approaches to protecting the authenticity of craft. In one we invest in the legal system, enforced by fines. And in the other, we engage in marketing, creating value in our brand. What’s it to be—the stick or the carrot?

To an extent, these alternative paths overlap the rich and poor duality. The ethical consumer tends to be a wealthier person, looking for a good story rather than just something that ticks the box. On the other hand, the lower end price sensitive market will not worry so much about authenticity In this case, we need more pre-emptive legal powers. I think there is still more potential in consumer-led protection. The customer forums that are increasingly prominent in the Internet offer greater scope for crowd-sourced whistleblowing.

What is the future for craft?

Clearly we cannot sum up Kaivalam without acknowledging the key question. ‘The future is handmade’ strikes a defiant tone. We make a bold challenge to the technological idea of progress which champions development as the replacement of human drudgery by ever more efficient machines. According to the technocrats, we are better off entrusting our world in machines, devices, clouds, rather than our own hands. It does seem unfortunately the default position of governments, but also sadly an increasingly popular attitude amongst many in the next generation.

Rather than succumb to defeatism, we take a stand. The future is handmade presumes we can leapfrog this purely technological idea of progress by anticipating a time when we realise that technology cannot answer our basic needs.

One of the quite deep aspects of Kaivalam was the way it reconfigured our understanding of time, particularly craft time. I liked the way Syeda Hameed quoted Rumi, including the line: ‘constant slow movement teaches us to keep working like a small creek that stays clear’. It’s not so much the linear flow of water, but its constant motion that is important.

There were many comments not just about the speed of progress, but also the narrowing of our time frame. Rolf von Buerren noted that the rhythm of life in the US is around five minutes, or the time between advertising breaks. Indeed, we are now witnessing an election campaign in the United States where the choice of leader in the largest world economy can be determined by a few minutes on the television screen. But more profoundly, we’re all still reeling from the devastation to our global economy caused by the intensification of short term profit by financial traders.

Craft is not so much about the past or the future, as what connects them together. As Octavio Paz wrote in that landmark 1974 World Craft Council publication In Praise of Hands, ‘The modern artist has set out to conquer eternity, and the designer to conquer the future; the craftsman allows himself to be conquered by time.’ At its core here is an acceptance of time, linking past and future.

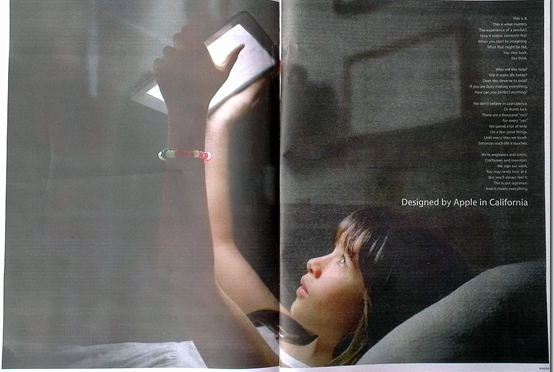

Arguably the most treasured consumer item at the moment is the Apple iPhone 5. It has truly miraculous powers and sports deviously clever apps. But how long will its value last? Will it ever be an heirloom? The value of these gadgets starts declining from the moment we purchase them. It’s the handmade object that we will entrust with our long term future.

On the one hand our tomorrow, on the other our children’s tomorrow. Craft stretches time. And as we need to face up to long-term issues like climate change, this role is increasingly important.

Four year journey

We may have started under the cloud of the GFC, but we’ve shared remarkable times together. I’ll never forget during Abhushan, listening to Ms Azza Fahmy from Egypt, on the morning the news broke about the change of leadership, how we could all share with her that solidarity that remains between those involved in craft, despite the upheavals that affect our world.

We’ve shared now in Kaivalam a great testament to the vibrancy of the ‘World’ Crafts Council. Beyond the formal presentations, we’ve had the privilege to meet people from 39 different countries, all brought together through a common interest in making beautiful objects that have a lasting place in our world.

Part of living in the world involves accepting that not everyone is the same. Rather than dilute our identity, diversity makes it stronger. There are at least two sides to the questions we’ve been considering over the past three days. Like the shuttle that moves across the loom, the play of opposites builds a stronger understanding of where we are.

On the one hand, and on the other. What do we do? Let’s put them together and congratulate Mrs Usha Krishna for leading us through the past four years.

The new publication Contemporary Jewelry in Perspective (Lark) helps realise the vision that Damian Skinner brought to his role as editor for Art Jewelry Forum (until 2012). As a New Zealander, Skinner has argued forcefully about the need to open contemporary jewellery up to perspectives from non-European cultures. According to his view, while the movement has its centre in Munich, its evolution in ‘peripheral’ regions such as Australasia and Latin America need not be seen simply as aspirations to European culture. The book includes contributions from Skinner himself (Australasia), Valeria Siemelink (Latin America) and Sarah Rhodes (Southern Africa) that identify the original contributions made from these regions to the broad global conversation about preciousness and adornment.

The new publication Contemporary Jewelry in Perspective (Lark) helps realise the vision that Damian Skinner brought to his role as editor for Art Jewelry Forum (until 2012). As a New Zealander, Skinner has argued forcefully about the need to open contemporary jewellery up to perspectives from non-European cultures. According to his view, while the movement has its centre in Munich, its evolution in ‘peripheral’ regions such as Australasia and Latin America need not be seen simply as aspirations to European culture. The book includes contributions from Skinner himself (Australasia), Valeria Siemelink (Latin America) and Sarah Rhodes (Southern Africa) that identify the original contributions made from these regions to the broad global conversation about preciousness and adornment.